Cables for ESP with Aluminum Alloy

Alloy advantages:

- Made from aluminum using chemical elements Zr, Fe, Si, Mg, Cu, Zn, Ni, B, V+Cr+Ti+Mn.

- Reliability, lightness

- Cheaper than copper

Permanent Magnet Motors

Cables with three main cores made of heat-corrosion-resistant aluminum alloy (TAS) with insulation made of polymer materials for installations of submersible electric pumps, designed to supply electrical energy to electric motors of oil production installations with a rated voltage of 3.3; 4.0 and 5 kV with an operating frequency range of 35-200 Hz. The long-term permissible heating temperature of the cable cores is 120-145°C.

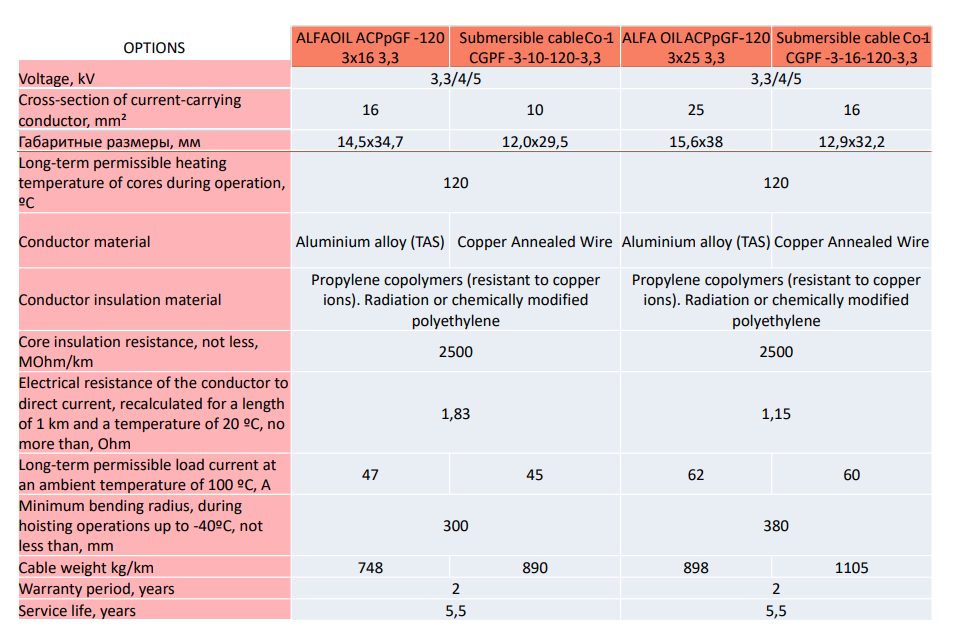

Cables for ESP with Aluminum Alloy Temperature Index 120-140 °С

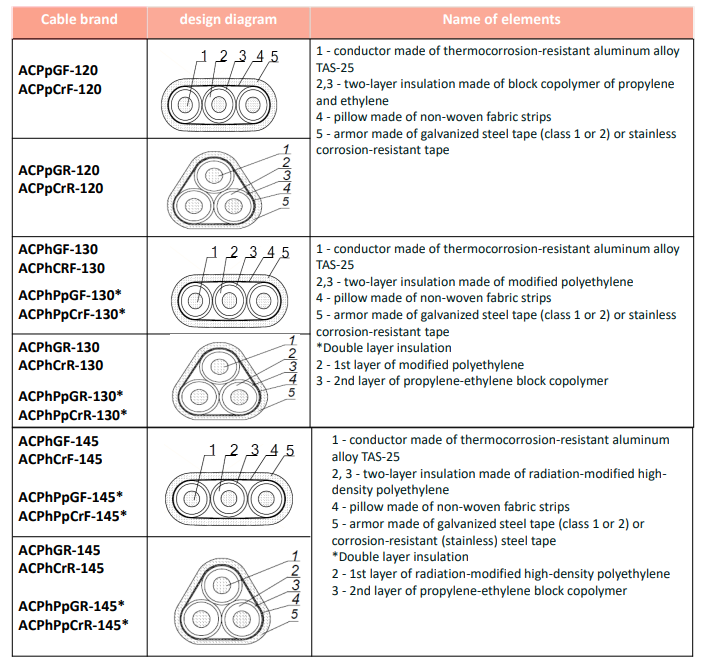

Symbols in cable brands:

- A – current-carrying core made of thermocorrosion-resistant aluminum alloy;

- C – cable;

- Pp – insulation made from a block copolymer of propylene and ethylene;

- Ph – insulation made of modified polyethylene or radiation-modified high-density polyethylene;

- G – galvanized steel strip;

- Cr – corrosion-resistant stainless steel tape;

- R – round;

- F – flat;

- 120, 130, 145 – long-term permissible core heating temperature, °C.

Comparative characteristics of the current-carrying core made of copper and TAC alloy: